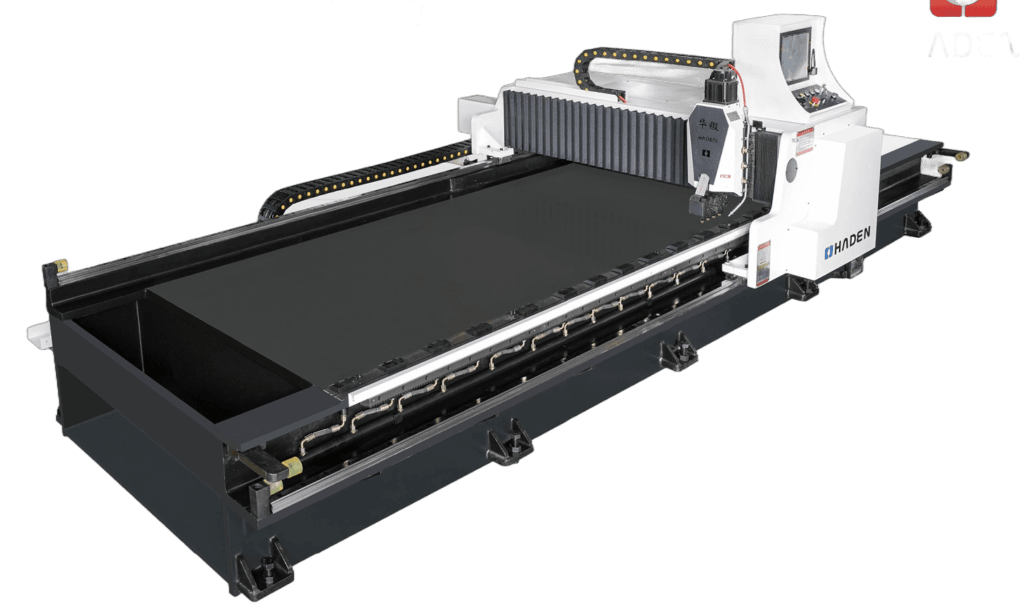

Servo CNC Gantry Grooving Machine

FULL SGRVO CNC VERTICAL SLOTTING MACHINE

- PRODUCT FEATURES

♦ Gantry style, convenient for loading and unloading. Air cooling without environmental pollution, with 3+1 axis CNC full servo control, achieving fully automatic operation and processing, improving the accuracy of groove machining.

♦ Using an imported hydraulic control system as the power, it has high pressure, reliable fastening force, low noise, and low energy consumption.

♦ Adopting precision grinding gears and 45 steel forged quenched and tempered helical rack guide rail transmission, the movement speed can be adjusted by frequency conversion, and the cutting process is stable.

♦ The CNC program design is reasonable and easy to master, and can be completed by inputting the machining dimensions.

♦ According to the different materials, the processing speed can be adjusted with a knob for easy operation by operators.

FULL SGRVO CNC VERTICAL SLOTTING MACHINE

- PRODUCT FEATURES

• HD-BL series gouging machine is an upgraded product of traditional gouging machine.

• Frame structure, high-strength bolt connection, good overall rigidity, small deformation.

• the crossbeam of this series is fixed, the workpiece is sent in by the back feeding mechanism, and the worktable is made of carbon tools. The hardness of worktable after high frequency surface quenching reaches 55- 60hc (ordinary worktable < 30hrc), which makes the hardness of worktable much greater than that of stainless steel. It solves the problem of groove mark caused by low hardness of worktable of traditional machine, ensures the flatness of worktable ± 0.02, and completely solves the deformation of worktable The problem of reducing the accuracy of V-groove extends the service life of the equipment.

• The front and back of the worktable are equipped with a supporting device to prevent the plate from being scratched during the processing.

FULL SGRVO CNC VERTICAL DOUBLE SLOTTING MACHINE

- PRODUCT FEATURES

♦ HD-BLS series grooving machine is an upgraded product of traditional grooving machines.

♦ Adopting a frame structure and high-strength bolt connection, the overall rigidity is good and the deformation is small.

♦ This series of crossbeams is fixed, and the workpieces are fed in by a rear feeding mechanism. The worktable is made of carbon tools, and the hardness of the high-frequency surface quenching reaches 55-60Hc (ordinary worktable<30hrC), which makes the hardness of the worktable much higher than that of stainless steel. This solves the problem of grooves on traditional models due to low worktable hardness, ensuring that the flatness of the worktable is < ± 0.02, and completely solves the problem of reducing the accuracy of V-grooves due to worktable deformation, Extending the service life of the equipment.

♦ Double planing head design, achieving back and forth planing, higher accuracy and faster efficiency.

♦ There are supporting devices in front and behind the workbench to prevent scratches on the plate during processing.